In a Q&A session, Virtek Vision’s CEO, Dietmar Wennemer reveals how the corporate’s laser projection options helps quickly enhance aerospace half manufacturing.

Processes resembling slicing, placement and lay-up on mould tooling can add substantial time to the manufacturing of carbon composite components in aerospace functions, notably when coping with massive constructions resembling wings.

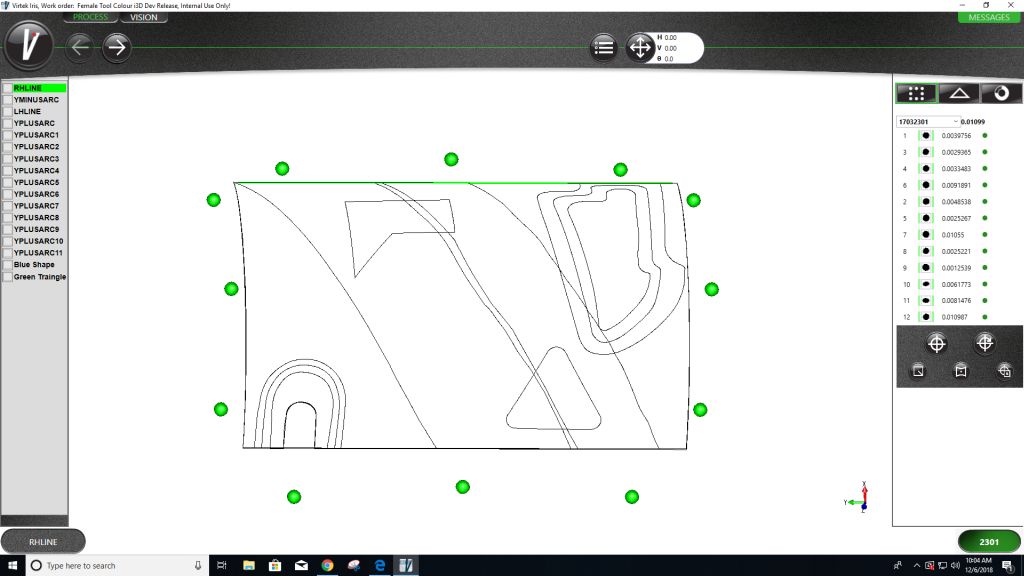

Virtek’s Iris software program platform together with the Vision Positioning System (VPS) permits operators to assemble composite components with out the usage of cumbersome bodily templates which have to be manually lifted on and off the mould whereas ply materials is mounted in place. The system tasks a laser define of the half or materials to simply information the operator.

Virtek Vision was a part of Gerber Technology till May 2021 and is now a PE-owned standalone firm once more. The firm continues to innovate within the laser projection and inspection subject, including new specialised engineering groups which can be engaged on new know-how for its prospects to assist them accomplish their Industry 4.0 targets. Virtek just lately upgraded its amenities at Canadian Headquarters in Waterloo, Ontario and invested in its Virtek Vision model as a standalone firm.

Q) What are the kinds of calls for positioned in your firm by immediately’s aerospace designers?

Virtek has a robust connection within the aerospace world and we all the time supply the private contact and wonderful customer support. Our steady innovation in know-how and collaborative partnering strategy has been setting the usual in aerospace for years.

Nowadays we see the power to ship, and suppleness on lead-time a massive problem as world provide chains turned stretched and challenged us too. We had been ready to construct up buffer inventory for our prospects and didn’t disappoint them, nevertheless it stays a massive problem for the approaching years.

Q) Primarily, what are your laser projection merchandise used for?

Virtek Vision has inspection and course of compliance capabilities built-in into its programs. Our VPS built-in stereo digital camera system, which options our patented FlashAlign and our auto focus capabilities are proving very helpful within the aerospace business for ply overlay and meeting. It supplies nice flexibility, precision and re-alignment pace that our prospects want for shifting instruments or tall ply layups.

Q) What are the chief advantages of laser projectors over conventional bodily templates and onerous tooling?

Virtek has an built-in SW system that permits for quick engineering modifications and work order administration. Our programs are digital built-in and could be pushed out of the engineering CAD system with out human interplay as a absolutely built-in automated course of. Additionally, our excessive visibility laser projectors are customary, and are best-in-class at offering a brighter secure laser delivering superior visibility even within the brightest work environments – with out requiring laser security officers, or eye put on safety.

Physical templates are pricey and have lengthy lead-times, particularly in immediately’s provide constrained world. Storage and administration of bodily templates is labour-intensive and requires certified private what’s increasingly more tough to discover.

Q) Is there any restriction regarding the dimension of aerospace parts? What ranges of accuracy and dimension do your laser projectors supply?

Virtek’s imaginative and prescient programs haven’t any downside projecting over very massive areas. Indeed, we’ve got some installations that cowl over 120m in size. We join many projectors collectively into a single system or a number of programs to cowl such massive areas. The protection of a single projector is said to the gap from the instrument or half. Virtek’s lengthy vary projectors are able to working on the longest distances of any within the business with offsets of up to and past 18m and naturally, all whereas assembly our prospects excessive accuracy necessities.

It’s all the time finest to seek the advice of our Virtek gross sales crew members, so we are able to perceive your business and utility wants as we’ve got a number of projection programs that present flexibility to our purchasers’ challenges. As a customary accuracy: ± 0.38mm or higher at a distance of 15’ over 4.6m x 4.6m space

Q) Can you challenge utilizing completely different colors – all on the similar time?

Virtek has the potential to challenge a number of completely different colors and we’re the unique patent holder for this know-how, however we recognized and confirmed during the last 35 years that the inexperienced laser wavelength to be the most effective seen and finest fitted to our functions. Red and yellow laser beams are tough to see (visibility and distinction on sure materials) and create challenges in actual world functions.

The Virtek laser projectors are used on a number of surfaces and embody wooden, plywood, metal, aluminium, plastic in several finishes and kinds, CFRP and plenty of others. Bright finishes in orange or yellow are a bonus to make the laser strains extra seen.

Q) What differentiates your merchandise from the competitors?

Virtek is an innovator by its core and we push the know-how limits – and can proceed to accomplish that. We are investing yearly over 10% of our income into R&D and our prospects profit from that. We have distinctive capabilities that our competitors can’t supply. The Virtek Long Range projectors, particular characteristic units, resembling ActiveTrack and FlashAlign with our IRIS 3D software program capabilities are distinctive and simply a few of the options that set us aside. Reliability, prime quality programs and ease of use are different key options for our prospects and we all the time ensure to enhance in these areas.

Q) Have your long-standing partnerships introduced enormous advantages, notably as trusted relationships can lead to a higher approach ahead for all?

Virtek has long-lasting partnerships – a few of them are over 30 years previous with prospects, companions and even suppliers in a number of market segments. That exhibits how a lot we worth our companions and it positively has labored very nicely for us and them.

We developed functions particularly for our long-standing prospects that made their workflow a lot simpler and manufacturing processes sooner, repeatable and created a greater high quality product for them. Our suppliers helped us push the bounds of know-how and labored with us to develop parts finest fitted to these functions. Our companions on the distribution and reseller facet labored with us to combine our programs into their know-how and made it a part of a higher general providing that helped resolve our joint buyer challenges.

Q) What developments if any do you foresee happening within the laser projector sector?

There are some disruptive applied sciences on the horizon. The laser projection know-how wants to evolve to forestall being changed by different applied sciences which can be cheaper, exact sufficient and extra versatile. Virtek is nicely conscious of those applied sciences and our Virtek InnovationLab prepares us for the longer term and the way to react to these disruptive applied sciences. Our prospects are guiding us into the following chapter of augmented laser projection and we’re supporting their course.

Q) Finally, some other enterprise?

A giant thanks to our prospects, companions, and suppliers for all of your help. Also, thanks to all Virtek staff worldwide who contributed to the success of the corporate during the last 35 years – we hope to proceed that success for years to come. It is an honour to be a part of the Virtek crew.

https://www.aero-mag.com/taking-a-shine-to-laser-projection